Category

Palerton 1.5 Ton High Pressure Industrial Natural Gas Steam Generator

Areas of application: 1. Washing ironing industry: dry washer, dryer and washing machine, dryer, ironing machine, electr

Basic Info.

| Model NO. | LSS 1.5-1.0-Q |

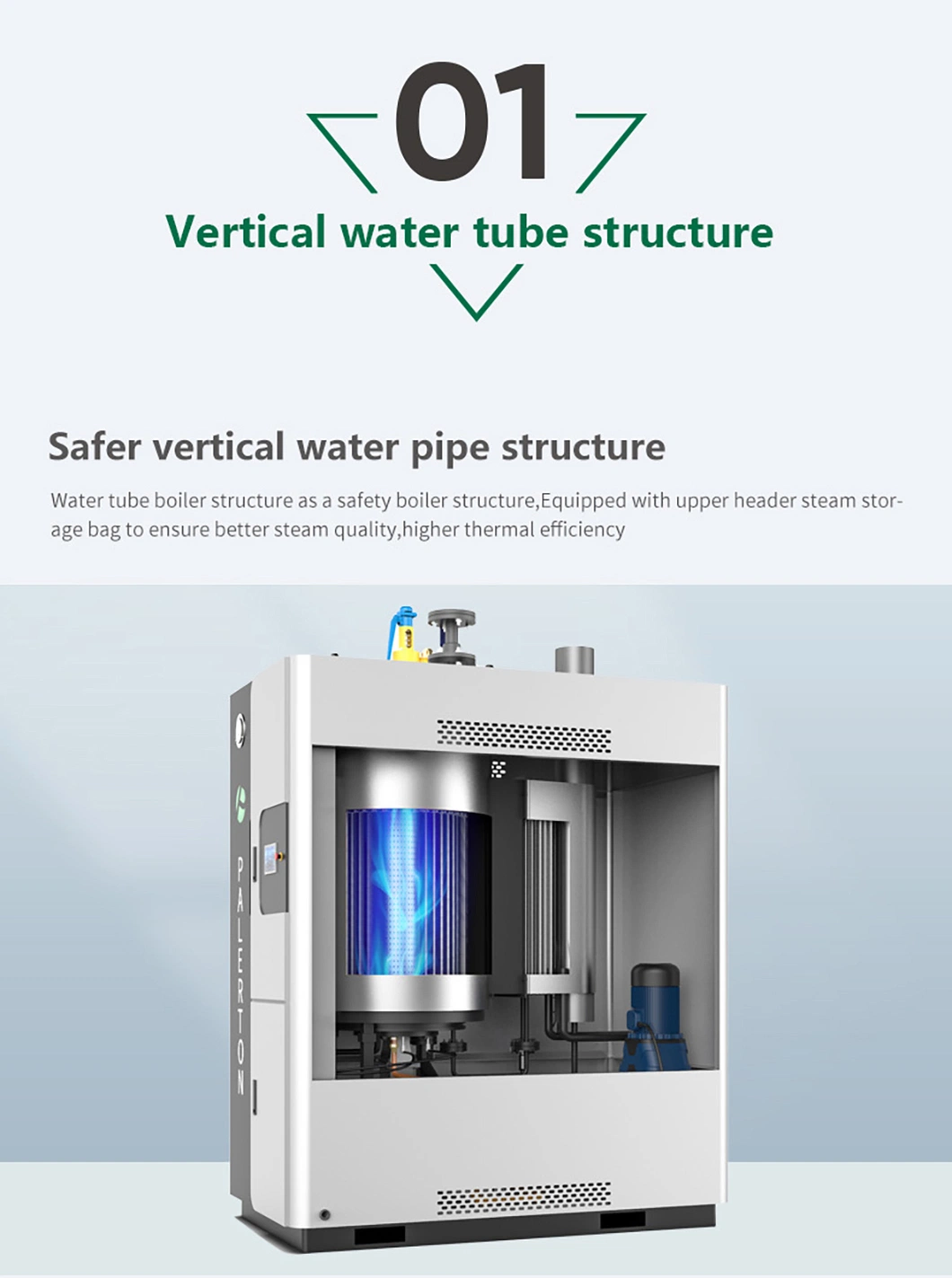

| Drum Placement | Vertical Boiler |

| Pressure | High Pressure |

| Manufacturing Level | B |

| Burning Style | Chamber Combustion Boiler |

| Usage | Industrial |

| Rated Steam Capacity | 1500 Kg |

| MOQ | 1set |

| Weight | 1700 Kg |

| Rated Pressure | 1.0 MPa |

| Transport Package | Standard Export Wooden Package |

| Specification | 2700*1250*2800 mm |

| Trademark | PALERTON |

| Origin | Shandong China |

| HS Code | 84021900 |

| Production Capacity | 1000 Sets/Year |

Product Description

Areas of application:

1. Washing ironing industry:

dry washer, dryer and washing machine, dryer, ironing machine, electric iron, and other ancillary equipment.

2. Food machinery industry:

tofu machine, steam box, sterilization pot, packing machine, coating equipment, sealing machine, such as supporting the use of equipment3. Biological chemical industry: Fermentation tank, reaction kettle, sandwich pot, mixer, emulsifying machine supporting the use of equipment

4. Other industries:

oil field, steam cleaning industry, (hotel, school, dormitory, batch plant) , concrete curing, leisure (salon), sauna bath, heat exchange equipment.

| Model | unit | LSS1.5-1.0-Q | |

| Rated steam capacity | Kg | 1500 | |

| Rated steam pressure | MPa | 1.0 | |

| Thermal efficiency | % | 100.35 | |

| Fuel consumption(natural gas) | NM3/h | 105-115 | |

| NOx emission | mg/m³ | <30 | |

| Power consumption | kw | <8 | |

| Power supply | Hz | Three-phase electricityfive-code cable | |

| Furnace | Furnace structure | / | Cross-chamber |

| furnace material | finned | Boiler carbon steel+316L | |

| Chimney diameter | mm | Φ108 | |

| temperature sensor | PT | 100 | |

| Steam outlet | mm | DN40 | |

| Saftey valve outlet | mm | DN40 | |

| Feed water inlet | mm | DN25 | |

| Sewage outlet | mm | DN40 | |

| Cooling water outlet | mm | DN25 | |

| Size | Size | mm | 2700*1250*2800 |

| Weight | kg | 1700 | |

| Combustion | Combustion method | / | Full Premixed |

| Combustion regulation ratio | % | 20-100 | |

| Valve group brand | / | Honeywell | |

| Valve group diameter(inlet) | mm | DN40 | |

| Gas static pressure | Kpa | 5-8 | |

| Ignition mode | / | Electronic electric ignitionSecondary ignition | |

| Fan brand | / | FASCO/USA | |

| Control cabinet | Control cabinet form | / | Embedded |

| Electric controlaccessories | / | ABB/Schneide | |

Automatic robotic arm

laser cutting machine

Package and delivery

Company profile

Palerton Group holding company limited established in 2007.Focus on the high-end steam boiler research and development,production and sales as the core business.One-stop steam energy solution provider.The group has nine major subsidiares and offices in 32 major cities across the country.

Palerton self-developed the FPTS cross-chamber full premixed surface combustion, High thermal efficiency 100.25% and Nox emissions reaching world leading level,Fully meeting China's strict ultra-low nitrogen emission requirement.

Our production base is located in Jian Jiangxi with more than 30000m2 construction area and jointly establish a research center for thermal equipment with the resources of scientific research universities.We strategic cooperated with XI'an jiaotong university and innovative R&D cross-chamber ultra low nitrogen technology achieves success in 2017. We have a team of 45 people including experts in the steam boiler field.Strong scientific research force ensures innovation strength.

Palerton is long term commitment to providing high-quality products and services for enterprises.Creating environmentally friendly ,efficient and energy-saving production methods.Enable million of enterprises to enjoy higher quality steam energy services.

Company Target:Becoming a leading brand in the steam industry!

FAQ

How to get a detailed and exact offer?

We help customer choose the best boiler model according to different requirements of various industry,Please let us know you required

steam capacity ,working pressure or fuel type,then we will send you the detailed and exact offer.

How long does it take to get the boiler ready?

Usually our company have new stocks ,we can manage the shipping within 2-4 days.We keep 24 hours online and keep close contacts

during the production process to ensure on time delivery.

Can you assist us to do the installation and operation trainings?

Yes,our company will provide the drawings and operation manual and also you can contact us for help ,then we will give you the technical supports online.

Way of delivery:By sea or Railway or truck based on need

Payment on terms:T/T L/C;30% deposit ;70% balace before delivery.